Article

6 min read

In service for Industry 4.0: What is machine vision? - Part 2

In the previous part of this article, we described in detail the concept of machine vision, one of the most exciting and dynamically developing areas of artificial intelligence. Now it's time to get down to the heart of the matter and show the applications and business benefits of this popular technology in different industries.

The inherent business potential of machine vision in different industries

There are several reasons why companies should consider integrating intelligent machine vision systems into their operational processes. They can make their operations more efficient - for example, improve the quality of their products or customer service - while reducing production and maintenance costs. The introduction of machine vision is an investment that pays off in the long term, so it is no surprise that it is already being used in many areas today. Let's look at some examples!

Healthcare

There are areas of medicine, such as ophthalmology, dermatology and dentistry, that benefit a great deal from digital imaging and image processing. Camera systems help to detect deformations and make diagnoses. For instance, a malignant mole can be identified with much higher accuracy.

Agriculture

Needless to say, the detection of damage caused by wild animals using drone footage, the identification of disease-stricken or infested areas, and crop yield forecasts provide really valuable information for farmers. This way, they can intervene in production processes more efficiently and more rapidly.

Quality control

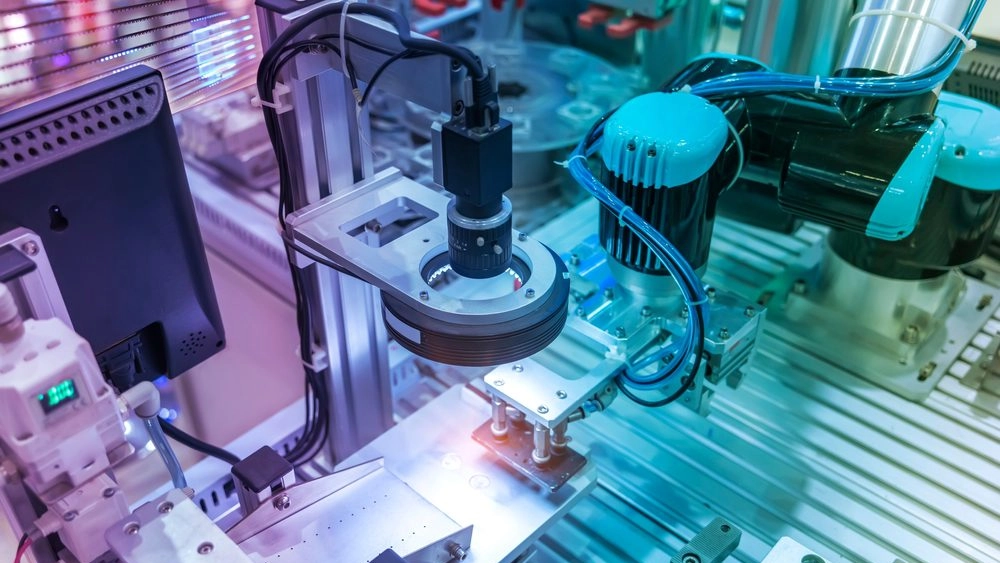

Modern image processing systems are also being used in manufacturing for quality control. They can be used to efficiently separate rejected scrap from conforming semi-finished or finished products in the production process, or to evaluate the quality characteristics of products.

The quality control process can be highly automated and its efficiency improved with advanced AI-based solutions. Since computers never get tired and moreover can analyse multiple parameters simultaneously, companies can improve quality, reduce production losses due to defective products, and suppress the number of customer complaints.

Machine vision-based quality control in practice

Just like a newly recruited colleague, artificial intelligence systems must be taught to make the right decisions. So, to create a seamlessly running quality control system you need not only a good camera, but also the right algorithm and inspection strategy that can be integrated into the given production processes. Take the example of scrap sorting:

First, a machine vision camera is used to record the products to be tested arriving on the production line.

The images are then used to evaluate the product: The artificial intelligence decides whether or not it is defective.

Finally, the AI decides whether the product can continue on the production line or is scrapped.

With machine vision, the sorting process can be executed in tens or hundreds of milliseconds for a particular product. This reduces the need for human intervention to about 25% of actions without AI. In addition, AI can be continuously taught and can work with increasing accuracy based on feedback, to inspect additional products or detect new types of defects.

Steps towards implementing machine vision: What are the difficulties?

First and foremost, corporate leaders must contemplate the future and be open to technological innovation. After all, by automating their operational processes they can gain a significant competitive edge over other industry players. Furthermore, it is always a good idea to set business goals and make profit calculations before implementing a technology.

Unfortunately, there is still a lot of unease and reluctance hanging around the use of machine vision, but these doubts can be easily dispelled by testing. After all, AI-based solutions are built on data, so preliminary tests can be carried out to prove whether or not machine vision can be applied with sufficient accuracy to a given product for a particular use.

In summary, we can conclude that the dynamic development of artificial intelligence provides an increasingly solid basis for integrating machine vision into corporate business processes. The automation of quality control itself is a truly significant step on the road to Industry 4.0 and digitisation.

With this in mind: Is your company interested in setting up automated product quality control with camera systems and machine vision? Take the first steps with us: Find out more about our services!